Our company ensures a complete range of needs from prototyping to the large scale production jobs. Our services include, Precision machining with the cutting edge technology our modern state of the art manufacturing facility offers the latest innovation in manufacturing technology. We are focused and meeting the highest standard and tightest tolerances in our manufacturing processes. Our five Axis vertical machining centers allows us to machining in five sizes apart in one operations. This production of part handling not only provides you the much more accurate part but also helps in reducing part cost. We produce top quality and static parts of wide range of materials, we are experts in machining of all types of material. we will consult with you to determine the appropriate material for your job. We use the most current estimating and job tracking software which allows us to follow your order all the way through production from the date order was placed to the final shipment. We work with the wide range of suppliers that enables us to handle all finishing process that required to give your parts a highest quality appearance available. Our quality control department uses the latest technology using both CMM and vision inspection equipments, our experienced inspectors are trained in geometric dimensions and tolerance inspection.

Our calibrated equipment allows us to maintain tolerances down to .0001. We work with the wide range of suppliers that enables us to handle all finishing process that required to give your parts a highest quality appearance available. At Micro India Engineering we take pride in exceptional customer service to quality products, on time delivery and competitive pricing.

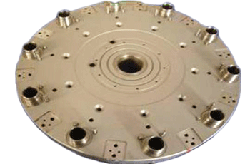

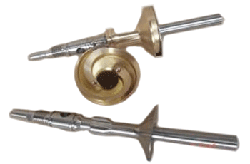

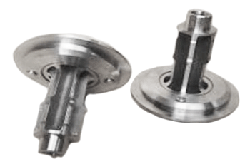

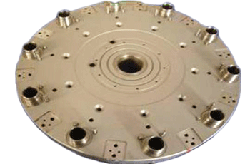

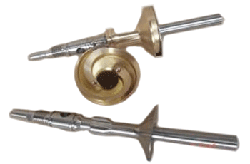

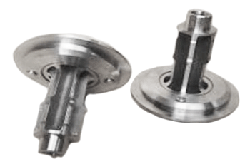

We provide Fully Machined ready-to-assemble components from Castings, Bar Stock or from Forgings for Gate Valves, Check valves, Butterfly valves, Ball valves, Control Valves, and other customized valves. Some of the main Valve components we provide are: Valve Bodies, Adapters, Bonnets, Discs, Balls, Wheels, Covers, Shafts, Spindles, Stems Seats.

MICRO INDIA has vast experience in manufacturing customized products for hygienic purposes, the food and beverage industry is extremely diverse. Specific challenges vary, but hygiene, and health and safety are common concerns across the industry.

MICRO INDIA has the core competencies to manufacture high quality pharmaceutical components that pharmaceutical companies can depend on. It is fundamental to maintain the high qualitative standard of the product and above all, to guarantee maximum functionality of the processing procedures.

This industry usually requires the products of various technological and engineering disciplines viz. aerodynamics. We at MICRO INDIA provides complex and quality products to this high-technology industry.

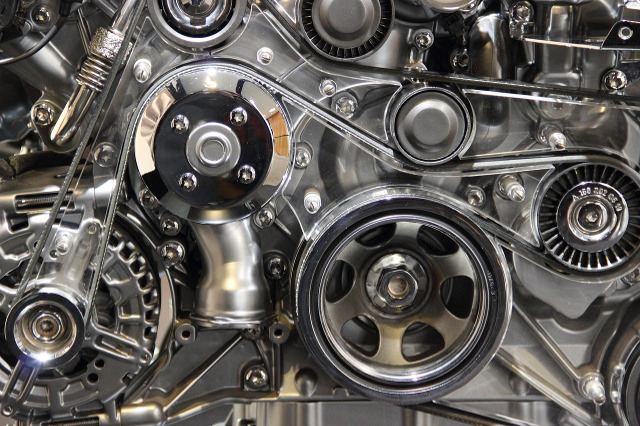

We serve for automobile industries, Machine manufacturing companies like jig fixtures, sub-assemblies, finished components from Castings, Bar Stock or from Forgings.

We offer components of a wide variety of designs and specifications for small precision turned parts including the manufacturing of products for chemical industry. Our products has cutting edge precision machining facilities designed to manufacture the small and complex parts. With diversified high production machines we meet a wide variety of design and specification requirements. In addition.

MICRO INDIA has a wide range of products in one place, which аre mainly produced by us, We offering wide range of “Stainless Steel, carbon steel and non-ferrous” and “Ready-to-Assemble components” for Valve and General Engineering Industry, Pharmaceutical, Dairy, Aerospace Industries machined from Castings, Forgings and Bar stock.

We are providing our customers with a wide variety of machining processes coupled with some in-house special processes capabilities. From machining services to fabrication work, MICRO INDIA is committed to delivering solutions that meet the needs of our customers around the world, backed by the latest technologies.

The structure of employees in our company is young, starting from the ownership structure of the company, director and highly-educated workers to the workers with secondary education. Such a structure of employees is suitable for further training and adapting to the latest technology and modern equipment used in various stages of production. We can say that we already have a young team of employees that will last and continue the trend of growth and development.

As the spindle torque is high in the medium- and high-speed range, the machine fully demonstrates its capabilities in high-speed, high-efficiency machining for aluminum or steel. Max. torque - 40Nm, Max. output - 18.9kW

The machine provides excellent turning capabilities due to the high-output turning spindle and the double plunger lock for the turning tool. The time taken for the turning spindle to reach the maximum speed of 2,000 min-1 is 0.3 seconds or less, leading to reduction in machining time. Max. torque - 55Nm, Max. output - 8.7kW